Galvanized traffic light poles are an important part of modern urban infrastructure. These sturdy poles support traffic signals, ensuring safe and efficient traffic around town. The manufacturing process of galvanized traffic light poles is a fascinating and complex process involving several key steps.

The first step in manufacturing a galvanized traffic light pole is the design phase. Engineers and designers work together to develop detailed plans and specifications for the poles. This includes determining the pole’s height, shape, and load-bearing requirements and ensuring it complies with all relevant codes and regulations.

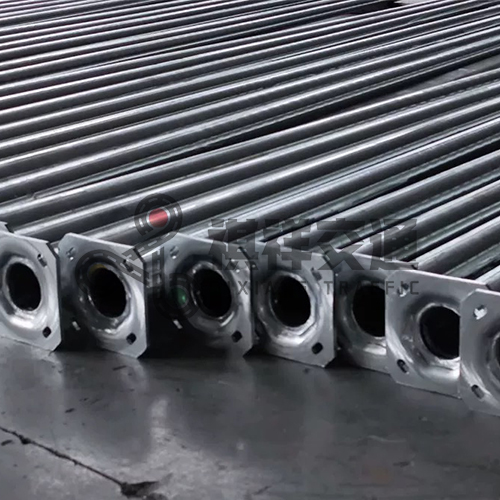

Once the design is complete, the next step is to choose the right material for the pole. Known for its durability and corrosion resistance, galvanized steel is the most common choice for traffic light poles. Steel is often purchased in the form of long cylindrical tubes and is used in the construction of utility poles.

The manufacturing process begins with cutting the steel pipe to the required length. This is usually done using a specialized cutting machine to ensure precise and accurate cuts. The cut tubing is then shaped and formed into the structure required for the traffic light pole. This may involve bending, welding, and forming the steel to obtain the correct size and geometry.

Once the basic shape of the rod is formed, the next step is to prepare the steel surface for galvanizing. This involves a thorough cleaning and degreasing process to remove any dirt, oil, or other contaminants from the steel surface. This is essential to ensure that the galvanizing process is effective and that the coating adheres properly to the steel.

Once the surface treatment is complete, the steel poles are ready for galvanizing. Galvanizing is a process of coating steel with a layer of zinc to prevent corrosion. This is accomplished through a method called hot-dip galvanizing, in which the steel rod is immersed in a bath of molten zinc at temperatures in excess of 800°F. When the steel is removed from the bath, the zinc coating solidifies, forming a strong and durable protective layer on the surface of the rod.

Once the galvanizing process is complete, a final inspection of the light pole will be performed to ensure that the coating is even and free of any defects. Any necessary touch-ups or repairs are made at this stage to ensure the pole meets the required standards of quality and durability.

Once it passes inspection, galvanized traffic light poles are ready for additional finishing touches such as mounting hardware, brackets, and other accessories. These components are attached to the pole using welding or other fastening methods to ensure they are securely mounted and ready for installation on site.

The final step in the manufacturing process is careful packaging of the finished poles for shipment to their final destination. This includes protecting poles from damage during transport and ensuring they are delivered safely to the installation site.

In summary, the manufacturing of galvanized traffic light poles is a complex and meticulous process that requires careful planning, precision engineering, and meticulous attention to detail. From the initial design stages to final packaging and delivery, every step in the process is critical to producing durable and reliable poles that play a vital role in maintaining safe and efficient traffic management in urban areas. The combination of high-quality materials and expert craftsmanship ensures that galvanized traffic light poles will continue to be an important part of urban infrastructure for years to come.

If you are interested in galvanized traffic light pole, welcome to contact traffic light pole supplier Qixiang to get a quote.

Post time: Jan-30-2024